Closing the Control Gap Before Chiplets and Advanced Packaging Leave You Behind

Purpose‑built Line Controller solution for chiplet integration in high‑mix semiconductor manufacturing

According to recent industry forecasts, the chiplet market is expected to surpass $50 billion by 2030. It is driven by the surging demand for AI, HPC, and automotive applications. The advanced packaging market is set to grow at a CAGR of over 10%, with 2.5D/3D integration and hybrid bonding becoming foundational technologies for next-generation devices.

What Are Chiplets—and How Can Manufacturers Seize the Opportunity?

Chiplets offer a modular approach—breaking large, monolithic processors into smaller, reusable die components. The real enabler, however, is advanced packaging, which integrates multiple chiplets within a single package to deliver higher performance and lower power.

For manufacturers, this evolution is not just a technology shift—it’s a market opportunity. Capturing even a fraction of this high-growth segment requires certain new investments in process control, traceability, and factory adaptability. Those who are ready with the right infrastructure, automation, and software—will be positioned to lead in a market that is quickly moving from niche innovation to mainstream demand.

Challenges Associated with Chiplets and Advanced Packaging

Although chiplet and advanced‑packaging architectures push the limits of performance and modularity, they introduce new engineering hurdles that demand focused solutions:

- Interconnect complexity: Chiplet integration requires high-density, high-bandwidth connections, which can be challenging to design and manufacture, especially in large scale production.

- Testing and validation: Testing individual chiplets and ensuring proper functionality can be complex.

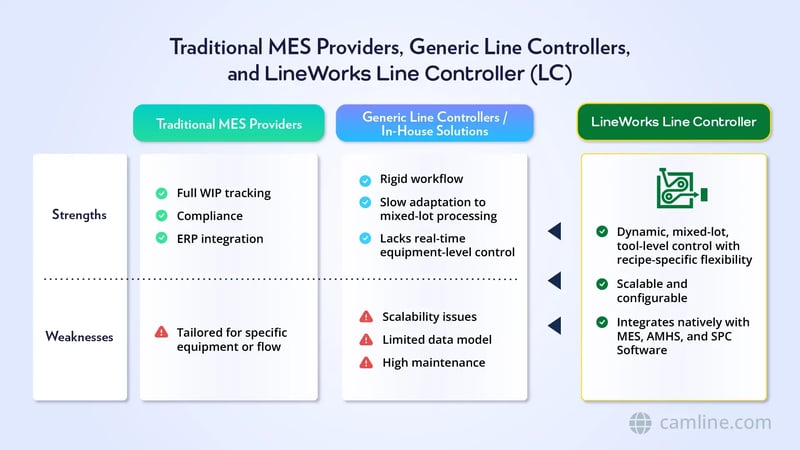

Why Traditional MES and Generic Line Controllers Struggle with Chiplet Lines

Many semiconductor manufacturers already adopt manufacturing executions systems (MES) as a means to tackle everyday production hurdles, but traditional MES wasn't designed to manage multi-lot, dynamic equipment routing or hybrid bonding process flows.

Unlike traditional linear wafer processing, chiplet production uses heterogeneous processing with different chiplets sharing the same tool but require varied processing steps. Standard MES architectures are not capable of tracking mixed-lot processing within a single tool efficiently.

The comparison below highlights why legacy control solutions—whether full scale Traditional MES platforms or Generic/In-House Line controllers—cannot keep pace with the dynamic, mixed lot demands of chiplet and advanced packaging production.

More Than an MES: Purpose‑Built Line Controller as Solution for Complex Chiplet Integration

Bear in mind that every manufacturing challenge has a workable solution. For chiplet production, the solution is a dedicated Line Controller (LC) engineered specifically for handling the complexities of chiplet integration & advanced‑packaging lines.

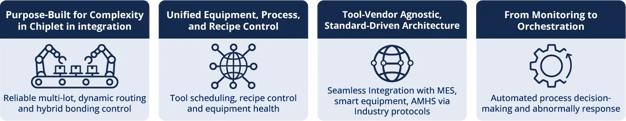

LineWorks Line Controller (LC) acts as the semiconductor industry’s precision line‑control platform—purpose‑built for real‑time equipment orchestration, recipe integrity, and performance management across high‑mix, multi‑lot flows.

Its event driven architecture delivers the exact, tool level execution required when chiplet lines switch tools or recipes mid process, setting the stage for unified equipment, process, and recipe control.

Unified Equipment, Process, and Recipe Control

While an MES tracks lots, LineWorks LC orchestrates the entire process itself, creating a closed‑loop manufacturing system for chiplet packaging lines. These are all possible through:

- Real‑time tool scheduling and routing: automatically adapts to tool status and lot mix.

- Recipe‑to‑lot matching with full version control: guarantees each lot runs on the correct, approved recipe, preventing mis‑processing.

- Continuous equipment health monitoring: detects drift early and triggers corrective actions before yield is affected.

Tool‑Vendor Agnostic, Standard‑Driven Architecture

While many solutions lock you into a single equipment ecosystem, LineWorks LC is designed for mixed‑vendor fabs and supporting integration with:

- MES, AOI tools, and AMHS

- Smart recipe changeovers

- Open industry protocols (SECS/GEM, GEM300, OPC UA)

From Monitoring to Orchestration

Most systems stop at data collection. LineWorks LC goes further using that data to drive automated process decisions making and abnormally response on routing, recipe selection, and tool maintenance. The result is a production line that not only reports its status but actively optimizes it in real time.

- Routing: automatically diverts lots around bottlenecks and faults.

- Recipe selection: applies the correct recipe version for each lot, tool, and condition.

- Tool maintenance: schedules preventive actions before drift affects yield.

Together, these capabilities position manufacturers to capitalize on the rapidly growing chiplet and advanced‑packaging market.

Seize the Opportunity to Be the Market Leader in Chiplets and Advanced Packaging

With its open architecture, LineWorks Line Controller extends seamlessly to LineWorks SPACE for advanced statistical process control (SPC). Scalable, highly configurable, and able to integrate natively with systems such as MES and AMHS, the combined platform delivers a single environment for chiplet production—covering everything from real‑time orchestration to predictive quality analytics. The result is consistent yield as chiplet demand scales.

Streamline process control, traceability, and factory adaptability with LineWorks Line Controller, paving the way for next‑generation chiplet and advanced‑packaging lines. Talk to an expert to learn how its capabilities can position your organization at the forefront of the semiconductor industry.

Explore More Pages

Discover valuable resources—from our latest news, events, and webinars to white papers—that offer insights into manufacturing automation and innovation.

Let’s Discuss Solutions with camLine's Experts

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.