LineWorks SEC

Statistical Equipment Control with Fault Detection and Classification (FDC)

Your Reliable Fault Detection Tool That Complements Your Advanced SPC

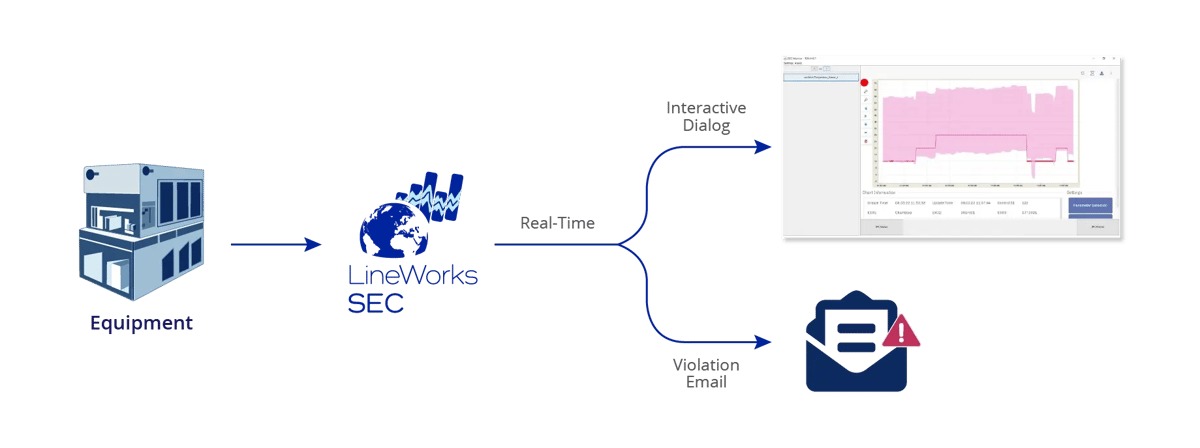

LineWorks SEC is an add-on module to LineWorks SPACE designed for real-time trace monitoring and Fault Detection and Classification (FDC).

Standing for Statistical Equipment Control (SEC), this feature enables manufacturers to capture and analyze process data within seconds whether from a single wafer, a lot, or an entire batch. Operating continuously 24/7, it monitors statistical data from production equipment, detects anomalies early, and helps prevent issues before they escalate.

Turning Equipment Data Challenges into Reliable FDC

Effective Fault Detection and Classification (FDC) require more than just capturing massive amounts of process data, it’s also about making sense of it in real time. With tremendous amount of data points generated at every production step, the real challenge lies in analyzing and correlating this data to correctly identify defects.

LineWorks SEC provides capabilities to:

- Collect, monitor, and process trace parameters (equipment data) in real time

- Conduct data review and analysis in seconds

- Have an effective data storage tracing method

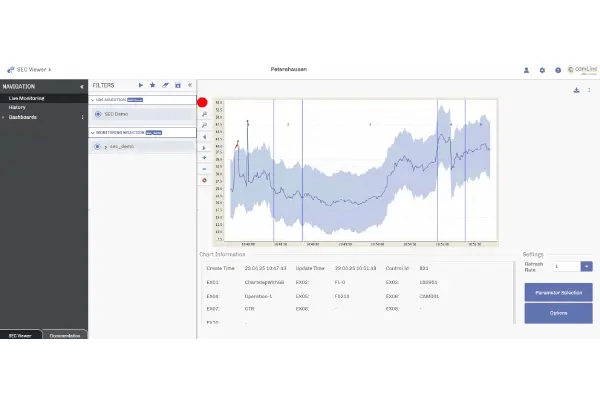

LineWorks SEC allows users to stream data live as it’s collected, seamlessly update dynamic visual dashboards. As new data arrives, the platform automatically refreshes interactive charts and graphs so that users can monitor trace and violation in real time without any manual refresh.

Capture and Analyze Equipment Data in Real Time

With LineWorks SEC, manufacturers can capture and manage production data with speed and flexibility. Equipment data can be streamed in real time, with every data point per second buffered into a continuous trace or collected in full once a process run has completed. This enables rapid real time monitoring, immediate analysis, and secure storage of complete process traces, giving manufacturers the ability to respond quickly and maintain consistent quality.

Trace Comparison Made Simple

Compare trace data visually using overlay mode or stack view. This makes it easy to spot deviations, similarities, or trends across different runs.

Real-Time Monitoring & Alerts

Stay on top of violations during data collection. LineWorks SEC notifies users immediately through alerts, pop-up windows, and built-in alarm systems, enabling rapid response to process deviations before they escalate.

Guardband Visualization

Clearly see guardbands (limits) for each trace, helping you identify when process values are approaching critical thresholds.

Flexible Data Handling

Combine multiple data collections across samples with powerful stitching functionality, making it easier to view complete runs as a single trace. LineWorks SEC also supports chart step visualization and provides calculated values per sensor for deeper insights.

Live Data Streaming

Users can stream and visualize process data collection in real time in the browser. This enables immediate feedback during production runs, supporting faster decisions and continuous process improvement.

Improved Efficiency

Streamlined Compliance

Greater Supply Chain Dynamics

Compliance Assurance

Data Collection Methods

LineWorks SEC offers flexible options for collecting data, designed to support the wide range of back-end processing equipment. These data collection methods include:

- LineWorks ECoFrame integration for seamless connectivity

- File input support (available upon request)

Beyond these standard options, it also provides flexibility on a project level. Custom data collection tools can be developed using Open Platform Communications (OPC) or RJG software, ensuring that even specialized equipment can be integrated smoothly.

Take Control of Your Production Data

LineWorks SEC delivers fast, accurate trace monitoring and classification. Designed to seamlessly complement your advanced SPC system, it captures, analyzes, and acts on production data in seconds for consistent quality, early anomaly detection, and uninterrupted manufacturing performances.

Explore More Pages

Discover valuable resources—from our latest news, events, and webinars to white papers—that offer insights into manufacturing automation and innovation.

/SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp?width=300&name=SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp)

Let’s Discuss Solutions Together

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.

/SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp?width=300&height=169&name=SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp)