SmartSPC

Automated Run-to-Run (R2R) Control System for Precision Manufacturing Excellence

Achieving Operational Excellence with SmartSPC

SmartSPC is camLine's integrated, modular automated process control system, built to empower run-to-run control in high-tech manufacturing.

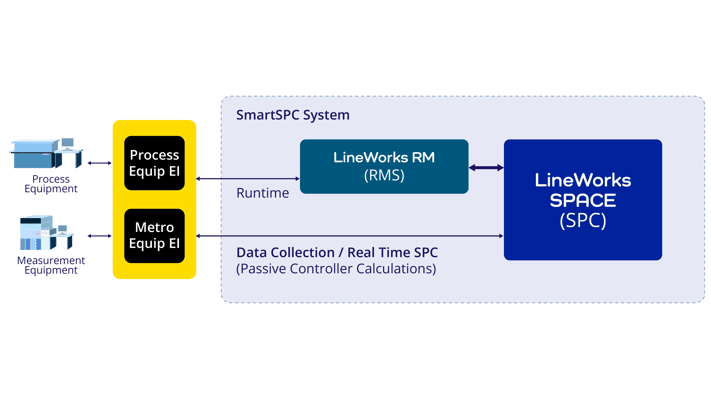

By combining powerful Statistical Process Control (SPC) from LineWorks SPACE with robust Recipe Management System (RMS) from LineWorks RM, SmartSPC automates process tuning, ensuring unparalleled precision and consistency.

Overcoming Process Control Challenges in High-Tech Manufacturing

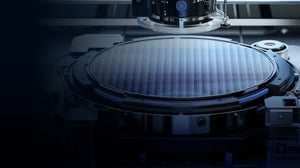

High-tech manufacturing, particularly in sectors like semiconductors, often relies on fixed process recipes combined with traditional statistical process control. This can lead to manual intervention and reactive adjustments, resulting in slower responses, increased scrap, and suboptimal production outcomes.

To excel in manufacturing, higher levels of precision and accuracy are essential, requiring tighter process control. Automated process control is therefore becoming a critical component to improve performance, yield, throughput, and flexibility, utilizing run-to-run, wafer-to-wafer, within-wafer, and real-time process control strategies.

Automated Process Tuning and Control System

SmartSPC automates process tuning by integrating LineWorks SPACE, LineWorks RM, and other components like Advanced Calculation Option (ACO) and Recipe Objects (ROBs). Using real-time data and advanced calculations, it optimizes process parameters for faster, more accurate adjustments. This helps achieve better process results, maintain consistent product quality, and improve production yield and efficiency.

LineWorks SPACE

The powerful SPC tool for comprehensive data collection and advanced calculations, handling metrology, process, and controller calculated data.

LineWorks RM

For robust recipe management, ensuring process integrity and precise parameter control.

Advanced Calculation Option (ACO)

A key component within LineWorks SPACE enabling automated process tuning through advanced data calculations for parameter optimization.

Recipe Objects (ROBs)

A key component of LineWorks RM that retrieves optimized parameter values in real-time for recipe adjustments.

RM Integration Layer (RIL)

The RM Integration Layer (RIL) facilitates the robust and seamless integration between LineWorks RM and LineWorks SPACE, forming the backbone of the efficient R2R control loop.

Equipment Interface (EI)

Integration point for real-time data exchange with your process and measurement equipment.

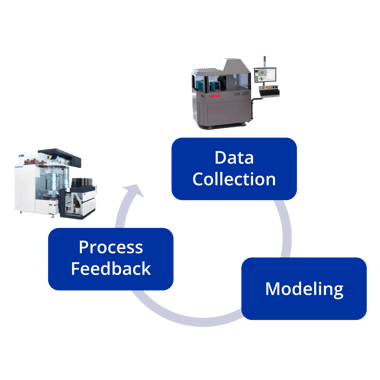

How SmartSPC Automates R2R Control

SmartSPC elevates R2R control through its intelligent 3-stage process, significantly advancing automated process tuning between production runs by using data collected from previous runs.

Modeling

The critical first step involves defining and setting the key process parameters and calculations necessary for optimized control.

Real-time Data Collection

Utilizing ACO from LineWorks SPACE, SmartSPC gathers precise production data and applies it to the previously defined model.

Process feedback

The evaluation of calculated results from the model to determine whether the production outcome meets the desired targets—enabling adjustments if necessary.

By optimizing tool recipe parameters and enabling dynamic recipe adjustments between machine runs, R2R control helps minimize process drift, shifts, and variability.

Key Benefits of Automated Process Tuning with SmartSPC

While traditional SPC primarily focuses on manual tuning to reduce out-of-spec (OOS) or out-of-control (OOC) products and scrap, SmartSPC achieves this transformation by consistently driving process control through automated real-time adjustments.

-

Streamlined Operations:

Automated process tuning through integrated ACO and ROBs ensures optimal production outcomes efficiently.

-

Optimized Recipe Management:

With tuneable parameters through SmartSPC and integrating with LineWorks RM, recipe adjustments are made automatically based on real-time data.

-

Reduced Defects:

Minimize process drift and variation between runs, leading to lower defects and higher yield rates.

-

Improved Quality:

Consistently meet high product quality standards across every batch with optimized tool recipe parameters.

-

Enhanced Process Capability (Cpk):

Improve Cpk by maintaining process stability through immediate fine-tuning and minimizing variability.

“SmartSPC significantly enhances process capability (Cpk) and supports more stable, efficient, and predictable manufacturing performance.”

SmartSPC Advanced Technical Capabilities

SmartSPC is built on a robust architecture designed for the complexities of modern manufacturing, providing unparalleled flexibility and control.

Advanced Calculation Option (ACO)

The advanced features of ACO from LineWorks SPACE include:

- Autocharting—Automatically charts calculated and intermediate parameters by creating channels based on defined population hierarchy.

- Application Programming Interface (API) call to retrieve samples using population lookup logic.

- Retrieve parameter values or equipment constants from RMS.

Recipe Objects (ROBs)

ROBs from LineWorks RM provide key functions including:

- Storing process parameters and equipment constant values used in calculations during automated process tuning.

- Defining SmartSPC tuning parameters and configuration to define how SmartSPC behaves.

- Uniquely matching the corresponding SPC channel for precise process control.

Transform Your Manufacturing: Get Started with SmartSPC

Discover how SmartSPC can transform your manufacturing process, reduce defects, and increase yield. Our experts are ready to discuss your unique needs and customize a software solution to help you overcome your industry challenges.

You might also be interested

Optimizing Semiconductor Frontend and Backend Processes for Greater Efficiency and Yield

Semiconductor manufacturing is a multi-stage process, from wafer fabrication and photolithography to packaging and final testing. Each stage presents unique challenges that require precise process control, automation, and data-driven decision-making to ensure high yield and efficiency.

/New%20Whitepaper%20Thumbnail/Whitepaper_Zernike%20Polynomials.webp?width=1921&height=1201&name=Whitepaper_Zernike%20Polynomials.webp)

Optimizing Wafermap Designs with Zernike Polynomials

Discover how Zernike polynomials and optimized sampling points boost wafer homogeneity, efficiency, and yield in semiconductor processes.

“SmartSPC—Integrates SPC and RMS systems to enable automated process tuning for dynamic, continuous recipe adjustments.”

Explore More Pages

Discover valuable resources—from our latest news, events, and webinars to white papers—that offer insights into manufacturing automation and innovation.

/SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp?width=300&name=SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp)

Let’s Discuss Solutions Together

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.

/SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp?width=300&height=169&name=SCHERDEL%20Medical%20Whitepaper%20Thumbnail.webp)