LineWorks SPACE

A Real-Time Software Solution for Enterprise-Wide Statistical Process Control (SPC) in Manufacturing

Advanced SPC Solution for Global Manufacturing Quality Control

LineWorks SPACE (Statistical Process Analysis & Control Environment) is an advanced SPC solution designed for global manufacturers seeking comprehensive quality control across their production sites. Trusted by leaders in the semiconductor and high-tech industries, it integrates both real-time and offline data, helping to standardize quality across all locations while ensuring compliance with ISO 9001 standards.

LineWorks SPACE, the flagship infrastructure solution for advanced SPC, provides you with complete control over production quality across all sites. It evaluates thousands of control charts in parallel, manages extensive data sources, and ensures traceability, helping you meet standards and maintain audit-ready records.

These customers already place their trust in us

LineWorks SPACE:

Solution for Effective Manufacturing Quality Control

Empowering you to maintain full control of production quality with enhanced visibility and faster decision-making.

Enhanced Production Quality Visibility

Monitor and analyze production quality across all manufacturing sites for better root-cause analysis and improved decision-making with real-time SPC.

Proactive Trend Detection

With trend analysis charts, it empowers you to detect trends early to identify anomalies and address issues before they escalate, driving continuous improvement.

Powerful Reporting Engine

An automated reporting system generates cyclic reports with real-time data, providing data-driven insights to support faster decision-making.

Scalable & Easy Integration in Production / IT Environment

Easily integrates new tools and technologies into existing systems, supporting growth and customer audits.

Corrective Actions with Built-in Guidance

Access corrective action tools and troubleshooting guides (TSG) for resolving out-of-control (OOC) events.

Regulatory Compliance

Be audit ready by having complete traceability and compliance with regulatory requirements such as FDA 21 CFR 11.

Continuous Improvement Strategies

Seamlessly integrate lean and Six Sigma concepts to drive operational excellence.

Key Benefits

Enhanced Production Quality Visibility

Proactive Trend Detection

Powerful Reporting Engine

Regulatory Compliance

Scalable & Easy Integration in Production / IT Environment

Corrective Actions with Built-in Guidance

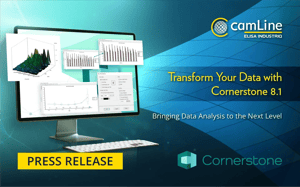

New Capabilities in LineWorks SPACE Release 8.1

Offering new functionalities for deeper process insights and more efficient data handling:

- Enhanced web-technology integration

- Improved visualization with SPACE Webcharts

- A flexible, familiar, and interactive browser interface

- Robust OIDC-based authentication

- Encrypted communication between clients and servers

- Ongoing support and compatibility for seamless operation

SPACE Monitor

Process control in real-time. Reaction to out-of-control events.

SPACE Navigator

Offline SPC, analysis, and administration.

Escalation Strategies

Notifications, corrective actions, and troubleshooting guides.

SPACE Dashboard

Speedy personalized access.

SPACE Reporting

Fully automated, configurable, and cyclic.

Core Features of LineWork SPACE

Providing advanced tools to streamline SPC operations and ensure process consistency across all departments and sites for all use cases.

SPC Rules/Evaluations

There are currently 81 SPC rules which can be turned on / off and configured on individual chart level to assist engineers in early detection of process variations for continuous improvement.

Dashboard

Provides up-to-date aggregated overviews of key performance indicators (KPI). dashboards support a fast access to the essential information by sorting, filtering, drill-down, and Pareto analyses.

Multi-parameter Charts (MPC)

Displays a unified view of multiple control charts for easier comparison and analysis. This enables real-time monitoring and visualization of measurements, enhancing control and decision-making.

Charts

Offers powerful graphical and analytical capabilities, enabling visualization of trends, distributions, and anomalies through features like histograms, Pareto analyses, and customizable.

Online SPC/Reactions

Helps users by quickly evaluating measurement data against control charts using customizable SPC rules, providing instant feedback to operators, engineers, and systems.

Automated Preruns

Calculates and check control limits automatically, which then sends the outcome notifications to specified groups of recipients for data-driven decision making.

Reports

Generates automated cyclic reports such as daily, weekly, monthly, or quarterly. In overnight batch processes, mass data are continuously summarized to process indexes.

“Widely used in the semiconductor industry, LineWorks SPACE handles thousands of control charts and processes millions of measurements daily, both online and offline, with minimal maintenance effort.”

LineWorks SPACE Extension and Add-ons

Comprehensive Integration Options to Enhance Your Process Control

To extend the capabilities of LineWorks SPACE, camLine offers a suite of integration add-ons for data collection and specific vertical applications such as defect monitoring or material disposition based on tester data.

SPACE Chart Plug-ins for Advanced Analyses

Graphs speak louder than numbers. SPACE Chart Plug-ins offer advanced analyses features directly at the graphical interface to operators and engineers. They expand the statistical analysis and visualization options for your existing data inside a SPACE chart to help you get more insight out of your data.

Ready to Optimize Your Manufacturing Quality with LineWorks SPACE?

Reach out to our team to discover how LineWorks SPACE can enhance your production quality and streamline your SPC processes.

You might also be interested

/New%20Whitepaper%20Thumbnail/Whitepaper_Line%20Controller.webp?width=1921&height=1201&name=Whitepaper_Line%20Controller.webp)

Line Controller for SMT Automation: A Collaborative Agent to Orchestrate Processes and Take Automation to the Next Level

Dive into how advanced line control systems can transform your manufacturing operations by navigating the complexities of SMT automation through enabling machine-to-machine (M2M) communication.

Enhancing Shopfloor Analysis with ML-Driven and SPC Solution

Discover how STMicroelectronics improves shopfloor analysis and anomaly detection with LineWorks SPACE and ML-driven SPC solutions for better process control.

“The scalability and reliability of LineWorks SPACE make it a preferred SPC solution for manufacturers aiming to enhance their Quality Management Systems (QMS).”

Explore More Pages

Discover valuable resources—from our latest news, events, and webinars to white papers—that offer insights into manufacturing automation and innovation.

Let’s Discuss Solutions with camLine's Experts

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.