Work Smarter — Achieve More

Discover how camLine software solutions can tackle your significant challenges across industries and all aspects of manufacturing operations and processes in the Work Smarter video series.

In today’s manufacturing landscape, manufacturers face growing pressure to boost efficiency, cut downtime, and uphold high-quality standards. camLine’s Work Smarter video series offers solutions by exploring innovative software and digital transformation strategies.

Currently, the series covers five key industries, providing tailored insights and best practices for each sector. Whether you are in SMT, advanced materials, semiconductor, or medical devices, these videos will equip you with the knowledge to enhance your operations.

-

All

-

Semiconductor Frontend

-

Semiconductor Backend

-

Surface-Mount Technology (SMT)

-

Advanced Material

-

Medical Device

-

Battery Manufacturing

Genesis of the Digital Twin for Recipe

Discover how integrated recipe management with a digital twin for recipes streamlines workflows, enhances efficiency, and drives semiconductor manufacturing excellence.

Read MoreOptimizing Recipe Management

Discover how optimizing recipe management with LineWorks RM simplifies workflows, reduces redundant components, and ensures consistent manufacturing processes.

Read MoreIntegrating Recipe Management with Your MES

Learn how integrating recipe management with your MES ensures secure recipe updates, centralizes storage, and enhances production efficiency with LineWorks RM.

Read MoreSmart Process Control for Semiconductor Backend Industry

Enhance semiconductor backend process control with smart SPC monitoring. Automate data collection, improve process uniformity, and boost yield with camLine’s advanced solution.

Read MoreDigital Transformation on the OCAP Process

Transform the OCAP process in the semiconductor backend industry with camLine's digital transformation solutions. Discover innovative approaches to enhance operational efficiency.

Read MoreTrend Grouping Solution in the Semiconductor Backend Manufacturing

Speed up root cause analysis and optimize semiconductor backend manufacturing with camLine’s Trend Grouping Plug-in. Gain deeper insights into production data with LineWorks SPACE Charts.

Read MoreData Collection Plan in the Semiconductor Backend Manufacturing

Optimize semiconductor backend manufacturing with a time-based data collection plan. Automate data schedules and ensure quality monitoring using LineWorks SPISE++ DCP.

Read More

Real Time Inventory Visibility in SMT Lines

Maximize ROI with real-time inventory visibility in SMT assembly line, enabling faster decisions and cost-efficient operations.

Read More

SMART Assist Line Setup in SMT

Optimize SMT line setup with camLine’s SMART Assist. Automate changeovers, reduce downtime, and improve first-pass yield in SMT manufacturing.

Read More

Transparent SMT Line Setup

Gain real-time visibility into SMT production with a bird’s eye view capability, allowing you to plan, schedule, and optimize SMT production lines seamlessly.

Read More

Process Monitoring and Control over Your Entire SMT Line

Enhance process monitoring in your SMT line with camLine MES for M2M communication and Jidoka autonomation concept—preventing defects before they escalate.

Read More

Process Time Control over Your Entire SMT Line

Improve SMT assembly line production quality with camLine MES solution, enabling precise process time control and equipment self-monitoring capabilities.

Read More

Equipment Supplier Independent SMT Line Monitoring and Controlling

Monitor and control your SMT line seamlessly with camLine’s Line Controller, ensuring supplier-independent integration, real-time visibility, and automation.

Read More

Digital Transformation with LineWorks SPACE Express

Accelerate digital transformation with LineWorks SPACE Express, a cloud-based SPC for real-time quality monitoring and proactive process control.

Read More

Qualifications and Compliance Made Easier

Automate customer quality management with LineWorks CQM. Ensure traceability, fast eCoA generation, and consistent quality across all supply chains.

Read More

Supplier Quality Management for Incoming Goods

Improve supplier quality management with LineWorks SQM. Automate incoming quality control, analyze supplier performance, and ensure consistent material standards.

Read More

Achieving Maximum Root Cause Analysis in Manufacturing Data on Incoming Materials

Improve root cause analysis in manufacturing with LineWorks SPACE Charts WIP Plug-ins. Track data, enhance traceability, and optimize quality control.

Read More

Maximize Efficiency and Reduce Waste via Auto Incoming Material's Shelf Life Checking Capability

Discover how LineWorks SQM (Supplier Quality Management) improves incoming material quality control with automatic shelf-life checking capability.

Read More

Document & Manage Medical Manufacturing Data

Learn how the medical devices industry can benefit from the right MES solution to ensure compliance, traceability, and quality control in manufacturing.

Read More

Traceability and Compliance with Global Regulations in Medical Device Manufacturing with MES

Achieve full traceability in medical device manufacturing with InFrame Synapse MES. Ensure compliance and improve audit readiness with MES solution.

Read More

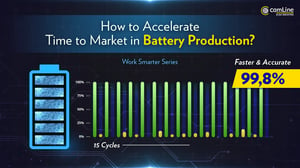

AI-Driven Solution for Battery R&D: Lifetime Predictor & Root Cause Analyzer

Discover how AI-driven Battery Lifetime Predictor and Root Cause Analyzer accelerate battery R&D cycles by reducing testing times from weeks to hours.

Read MorecamLine's commitment to digital transformation ensures that our software solutions enable manufacturers to navigate the industry's demanding challenges today and beyond.

Explore More Pages

Discover valuable resources—from our latest news, events, and webinars to white papers—that offer insights into manufacturing automation and innovation.

Let’s Discuss Solutions with camLine's Experts

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.